Description

This construction is in Germany often as “White Tank” called. It is initially for the construction of basements (in groundwater) systems used. Bottom plate and outer walls of a closed tank made of concrete with a high water penetration resistance in accordance with DIN EN 206-1 and DIN 1045-2 manufactured. This concrete is also called water-impermeable concrete or waterproof concrete. Expertise and careful approach to planning and construction are key to a proper and even dense basement.

In addition, a possible chemical attack level of groundwater must (…) be determined, then in the exposure classes XA1 to XA3 (chemical attack) is considered. What the basement the groundwater, that is the pool his content of water. The chemical attack on the concrete comes naturally from the chlorine. The chlorine reacts with the carbonate in the concrete, which should ensure the protection of steel in concrete. This decarbonation reduces the strength of the concrete , allows water to penetrate to the steel and swell the volume of the steel by corrosion on the up to 4.8 times . Therefore, the coverage of the steel by the protective concrete must be substantially thicker than normal basement (50mm). This increases the wall thickness for a pool.

Depending on the thickness of the concrete is also the time, in which the concrete is reducing its volume. This is done by chemical processes and the drying out of the water. This is an exothermic process, which is as “"dwindle"” called. Shortening or reduction in volume of the concrete over time is due to moisture loss (dry out) and by chemical reactions or transformations of the microstructure of the concrete. Under unfavorable conditions, for example in floor ceilings in closed buildings, the linear reduction is up to -0.6 mm/m. With a 50m pool without joints, the length would increase only by this process 30 millimeters.

Construction time

The guidelines of the tile manufacturers therefore provide different procedures for testing. It is advisable, to calculate the construction period as follows:

- Hardening of the concrete 30 days, depending on the environmental conditions,

- Check filling with water, 10 days watching moisture and mark,

- Draining and drying,, at least 10 days,

- Drill into cracks and squeeze with epoxy resin, 10 Days for the reaction of the epoxy resin,

- Check filling with water, 10 days watching moisture and mark,

- If additional leaks are found, repeat steps …

- Empty pool and dry until residual moisture is below the manufacturer's instructions for tile adhesive., closed building about 30 days,

The sum is 90 days. Only then the tiler can be started with the work. The tiles must be in the floating-buttering method (without voids under the tiles) be sticked on.

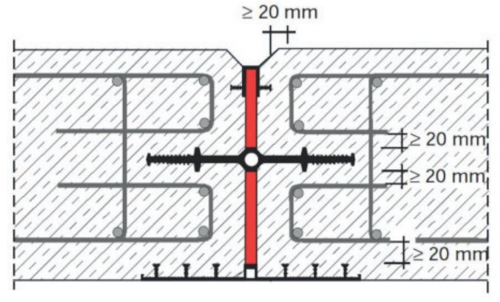

Joints of the concrete

Basements are sometimes large, but the size of a swimming pool they do not usually. Therefore, it is not usually possible, to build the entire body without joints. Here we find the first weakness for novice architects. Because the connection via a joint must remain tight for a long time under the influence of chlorine.

Source: Sika Germany GmbH, Seal for joints 4006

Subsequent work on the joints is excluded. For corners and other compounds form fitting parts from the manufacturer are available.

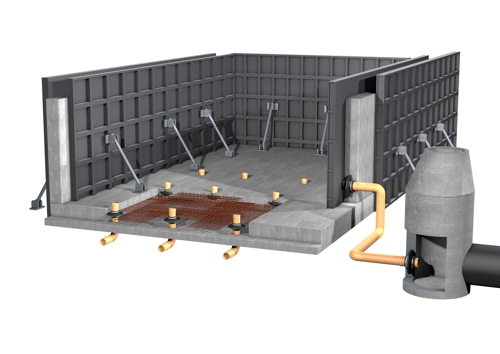

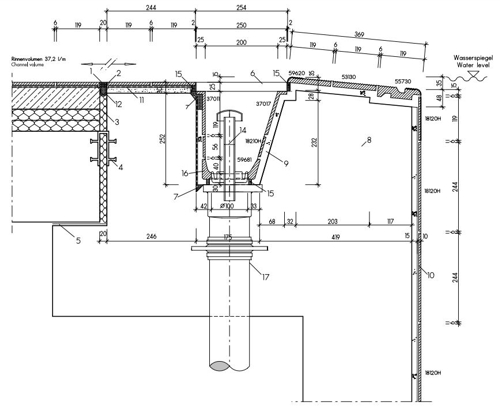

But a pool consists not only of a box of concrete. For water supply and discharge or lights the concrete must be often penetrated. Usually these are pipes, which have previously been located in the concrete. Again, the tightness must be secured in concrete. A common example looks like this.

Source: www.frank-gmbh.de/

Each individual penetration is provided with at least one seal. Due to the shape of the plastic, the path of water at the connection extended to the concrete. The metal visible in the picture is protected from corrosion by the surrounding concrete.

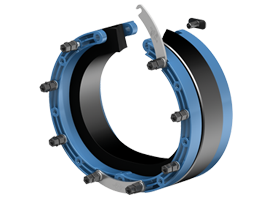

Source: www.frank-gmbh.de/

Should be installed parts later in the wall, then a solution exists too. For these penetrations of the concrete including the steel can be pierced. The bore hole is substantially greater than the diameter of the tube. This solution is not cheap and is bound by conditions. The thickness of the concrete layers without steel is particularly important . In addition, the static reserve must leave the hole.

Source: www.doyma.com/dichtungssysteme/produktfinder/dichtungseinsaetze/gegen-drueckendes-wasser/

In the sealing metal parts are present. Again, the influence of water on the corrosion has to be considered. Stainless steel is not suitable.

Source: aqua&pools

Painting

If the formwork removed, then a relatively rough concrete is the first result. The pores of this surface is a good place for organisms. It is therefore necessary, to close the pores with a suitable chlorine-resistant protection. At the same time, of course, a coating increases the resistance of the concrete to the chloride. In addition, the dissolution of the mineral components of the concrete is prevented. In my experience, the product “Aquafin 2k” the company Schomburg gives good results for the tanks of water treatment . But this product is cement-gray, therefore it is not very suitable for visually beautiful pools.

Of course, the easiest visual enhancement, to use an appropriate color. Here so-called chlorine rubber paints were used in the past. Chlorine rubber is very similar to PVC, it is converted from a polymer in a thermoplastic. Note the concentrations of carbon tetrachloride in the product. Applies to both products, that the separating oils for good adhesion must be avoided or removed from the formwork construction .

Even coatings with polyurethane can be used as protection and visual enhancement. Here is a short video of the manufacturer “PU Solutions”:

Ceramic tiles

Mineral joint adhesive and the concrete reduce the Free chlorine. Are behind the ceramic hollow spaces available, then this is the retreat room of organisms. Heat and nutrients abound, that these organisms degrade the water. The ceramic must therefore be processed without cavities. Called the “Floating-Buttering-Method”.

Joints between the ceramic

Rigid joints can destroy the ceramic and lead to very dangerous cut edges on the ceramic. There is a risk of injury here! Expansion joints of concrete and ceramics must be positioned above one another. All other joints of ceramic to ceramic must also be flexible. It should be noted, that the epoxy compounds may submit any organic matter in the water. Depending on the manufacturer therefore has a period of approximately between processing of the epoxy and the filling with water 30 days to wait.

Joints made of silicone

Special silicone for the swimming pools is resistant to chlorine. Pure silicone is mineral. But in the processing of normal silicone often organic additives are used. These additives feed algae and cause discoloration of the joints. Check the suitability of the silicone.

Almost every tiler uses normal detergent to smooth the joint. The ingredients of the detergent bring organic matter in the silicone. The tiler must use special silicone of the manufacturer as lubricant. As usual, the magic word is here “System manufacturers”.

Tolerances in the realization

The safety rules result in tolerances, which are not common in normal buildings. This also applies to secondary dimensions, arising from the special function of the pools. These “normal” tolerances are specified in DIN 18201 and 18202 and well described. The architect should not miss, the “higher requirements” to formulate the accuracy as in DIN prior to the offer and to fix in written contract.

For example, if a movable floor “Hubboden” is to be installed in the pool, then the pool must be vertical in all walls with high accuracy. The gap between the wall and the movable floor must be smaller in every position of the bottom and in each region of the circumference 8 millimeters. (EN 13451)

When a movable bridge is to be used to change the length of the swimming path, then applies the same value (8 millimeter) for the gap between the bridge and the wall or bridge and channel too. May need to be calculated beforehand, have what water and air temperatures and which expansion of the components in the pool could therefore be present.

Hydraulic system

In this pool construction, the hydraulic system can be used with the nozzle in the pool floor or in the pool wall. For nozzles in the wall, the weakening of the static is to be considered. For nozzles in the pool floor is important, in which position the pipes and fittings for uniform distribution of the water are positioned. If the tubes between the steel should are intended, then often a greater thickness of the bottom is required. It has to be taken into account, that also the nozzle itself have a sufficient distance from the steel and need to be integrated in the seal.

If not hollow space is planned under the pool, then the pipes must be installed under the pool is usually befor the entire building.

Details and calculations to the hydraulic system will follow the same called tutorial.

Emptying the pool

There are national differences in the assessment of the depth of a pool. In Germany, the magic number of valid 1,35 Meters of water depth. Larger water depth means greater risk for user. Conversely, it is in starting blocks and diving equipment. Here a minimum water depth is required to reduce the risk to the level of insurance regulations. It does not matter, if the slope is necessary. The planning of the slope must be included in the calculation and assessment of water depth.

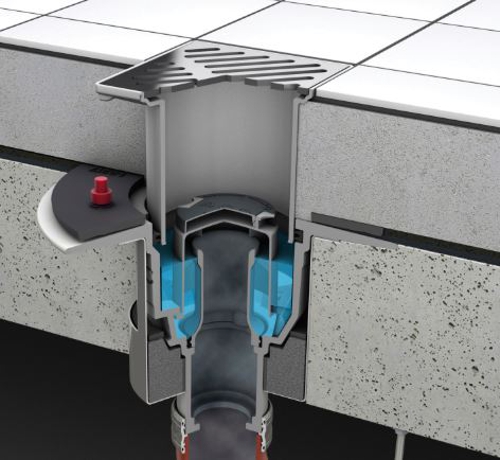

Connection to the sealing of the environment

Of course for pools in the building, the sealing of the pool must be connected to the sealing of the room. This is especially important, if the water level is higher than the surrounding area of the pool. (See drawing below) The water can migrate on the sealing layer beneath the tiles, and exit in the area of sealing the space upwardly through the tiles. Therefore, the sealing of the room has to be dewatered in a sealing plane. Drainage of the tile surface is not sufficient.

Source: ACO Tiefbau Vertrieb GmbH,

Construction of the pool

If you understand the sealing function of the concrete and the built-in parts, then the construction can be started. In each step of this construction but the previously formulated propositions must be respected.

Presumably these principles to an average wall thickness of at least 40 lead cm. This yields per square meter pool wall weighs 2,6 tons of times 0,4 Meter = 1,04 metric tons. The water in a pool 25x10x1,85m weighs 463 metric tons. Only the reinforced concrete of the same size pools already weighs 432 metric tons.

The design shall be such, that the required accuracies are maintained at the end of the process. The reduction of the volume of the concrete must not lead to an unplanned change in the length of the pool or to a considerable deformation of the overflow edge.

The dead weight of the pool must not alter the foundations or the supporting structure. The Lay-on forces other components, for example, the edge at the pool head, must also be observed.

All this represents a major challenge to the structural engineer, who is to calculate the pool of one millimeter. From the beginning, have to be included:

- Net internal dimensions of FINA standard,

- Spreads for slidable bridges,

- Bonuses for ceramics,

- Spreads for the ceramic adhesive (Attention special procedure),

- Tolerances in the construction of the formwork,

Qualified architectural offices start their activities so with the creation of a plan for laying the tiles and bring the pool dimensions and position of the joints in the plan in accordance.

Source: www.agrob-buchtal.de/

Therefore, taking into account all points very beautiful and durable pools can be built. The price of the pool depends on the “waterproof concrete” and the many special parts.

The following pages…

will present the different construction types and associated materials of pools. But this is not done in a Pro- and contra-form. Instead, as neutral as possible description of the important points from my own personal opinion and experience. The assessment must make every reader for yourself.

Have lots of fun with it!

Leave a Reply

You must be logged in to post a comment.